In order to improve the competitive advantage of the market, Zhejiang Hongfei Machinery has always insisted on vigorously supporting technology research and development, continuously optimizing production process, strengthening self-manufacturing ability and improving design ability. To provide more excellent products to meet the different needs of customers.

From September 3 to 5, 2019, Zhejiang Hongfei Machinery invited engineering and technical experts from Foseco, the casting material leader, to conduct in-depth cooperation with Hongfei Machinery and jointly study the casting process of wear-resistant parts. Foseco is the world’s leading supplier of casting consumables and solutions. Foseco provides a full range of consumables and technical support to help foundry enterprises to improve casting quality, reduce production costs, and produce high-quality castings efficiently and environmentally friendly.

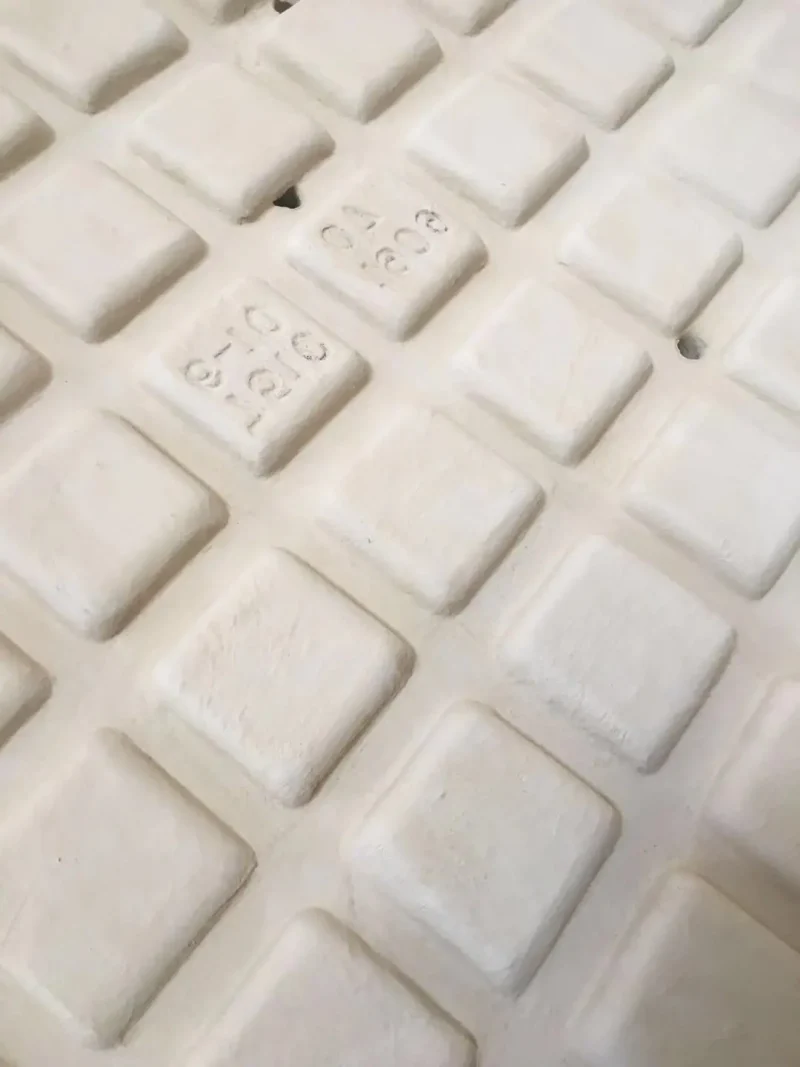

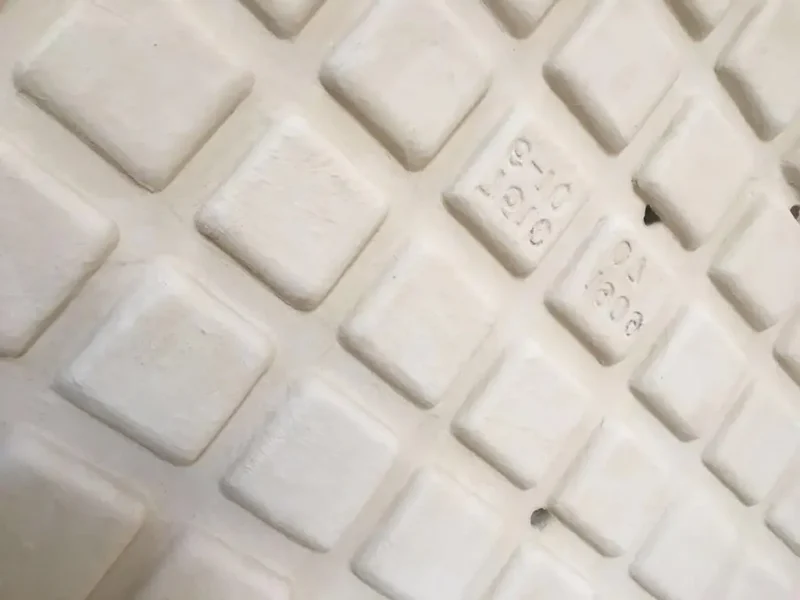

With the improving demand of the quality of wear – resistant casting from customers, the casting technology must keep pace with the market. Hongfei Machinery continues to invest in the research and development of technological innovation, improve the casting mold and the precision of the mold, so as to improve the manufacturing level of wear-resistant parts casting industry.

Foseco experts and Hongfei mechanical technicians went deep into the production line for three days, and through structural analysis and technological analysis, then put forward the technological upgrading plan for the sand mold casting process for Hongfei. The technicians carried out a large number of technological tests in Hongfei workshop, repeatedly simulated and tested, and then selected high-collapsible sand to make mold core, and adopted new binder and coating for the casting process of sand core and sand mold. This process upgrading ensures that the casting surface is complete and clean, reducing or eliminating casting defects. Hongfei constantly improve the mold technology to create unparalleled quality products, in order to win a better market reputation.

As a leader of wear-resistant parts manufacturers, Hongfei Machinery is not only committed to creating first-class wear-resistant parts, but also deeply devoted to the field of engineering machinery accessories. What we want to create is an environment-friendly, green and safe casting enterprise. Adhering to the production concept of energy saving and environmental protection, Hongfei Machinery provides employees with a clean production environment, reduces the emission of pollutants, plays a good defense for blue sky, and maintains the green mountains and waters around the enterprise.