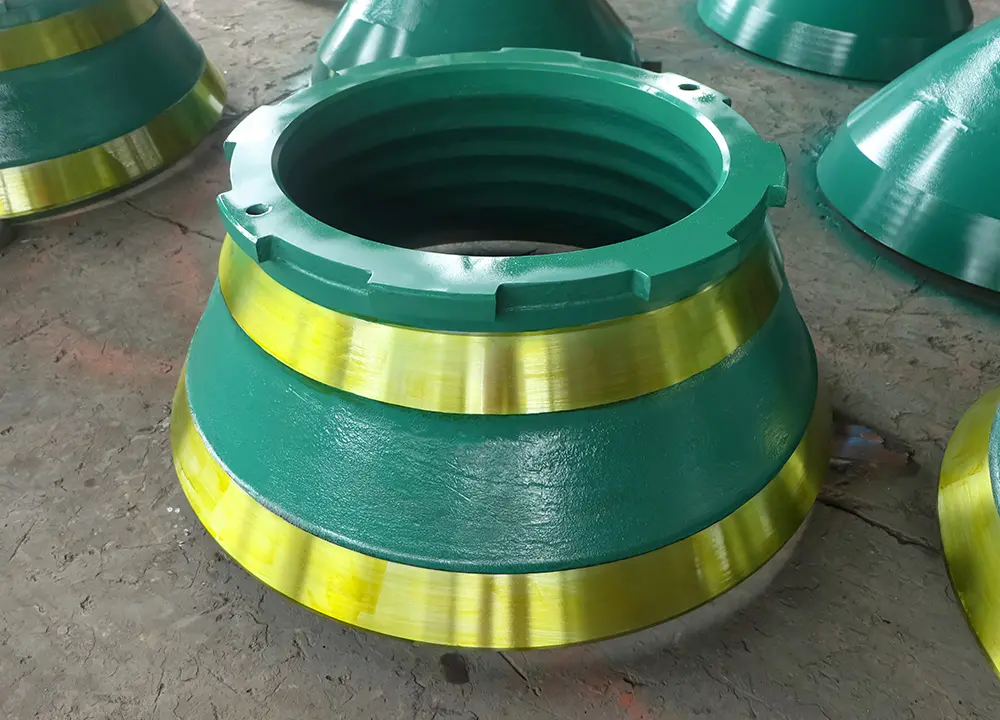

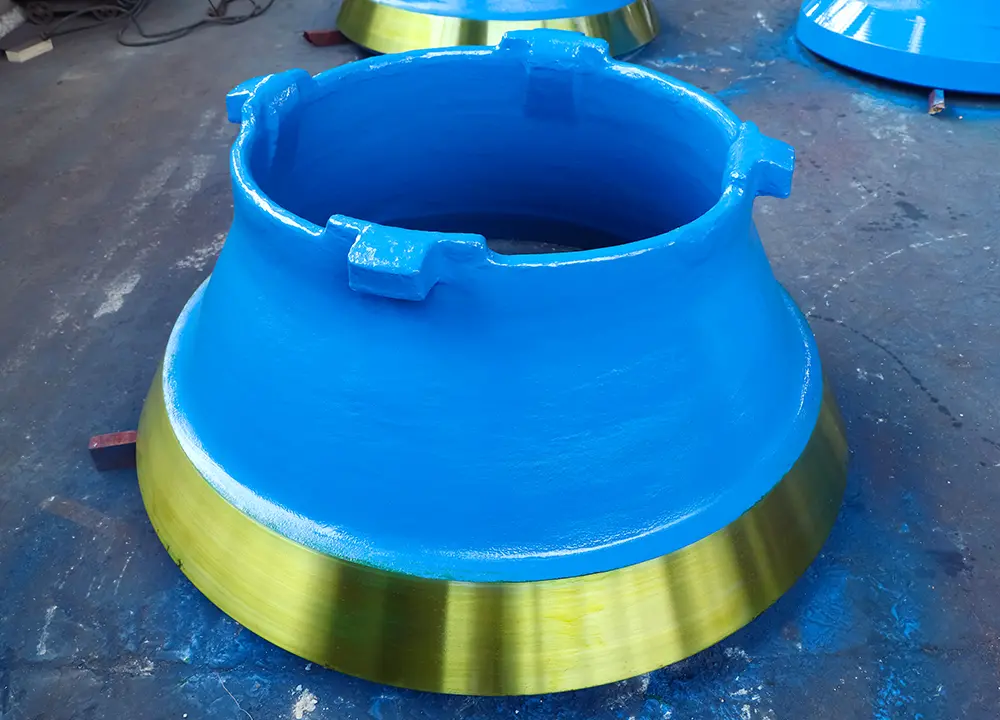

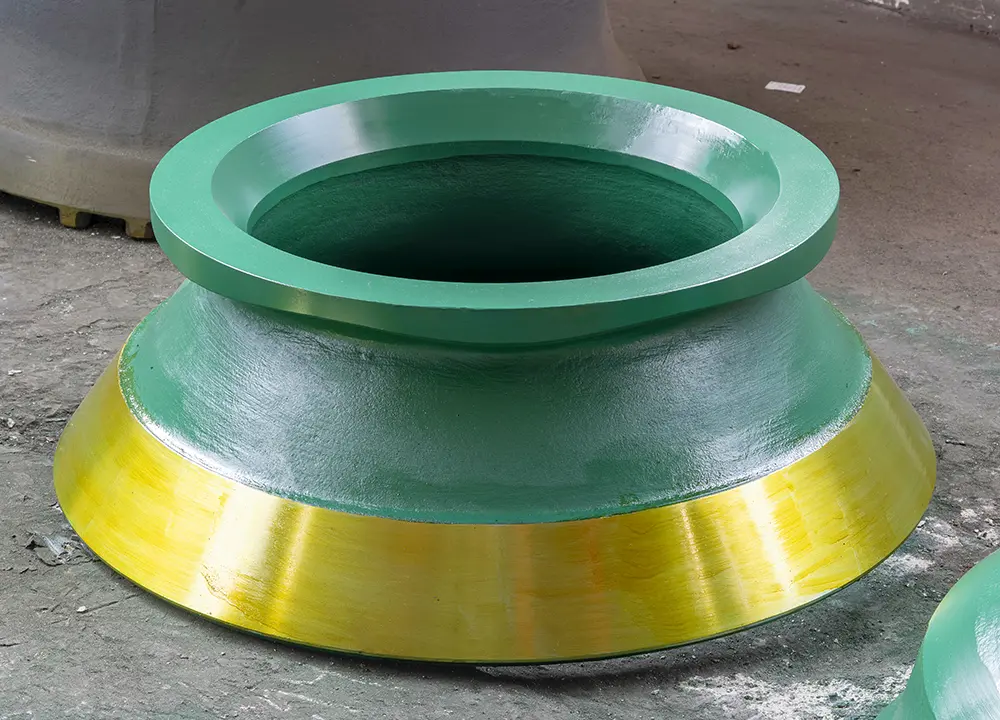

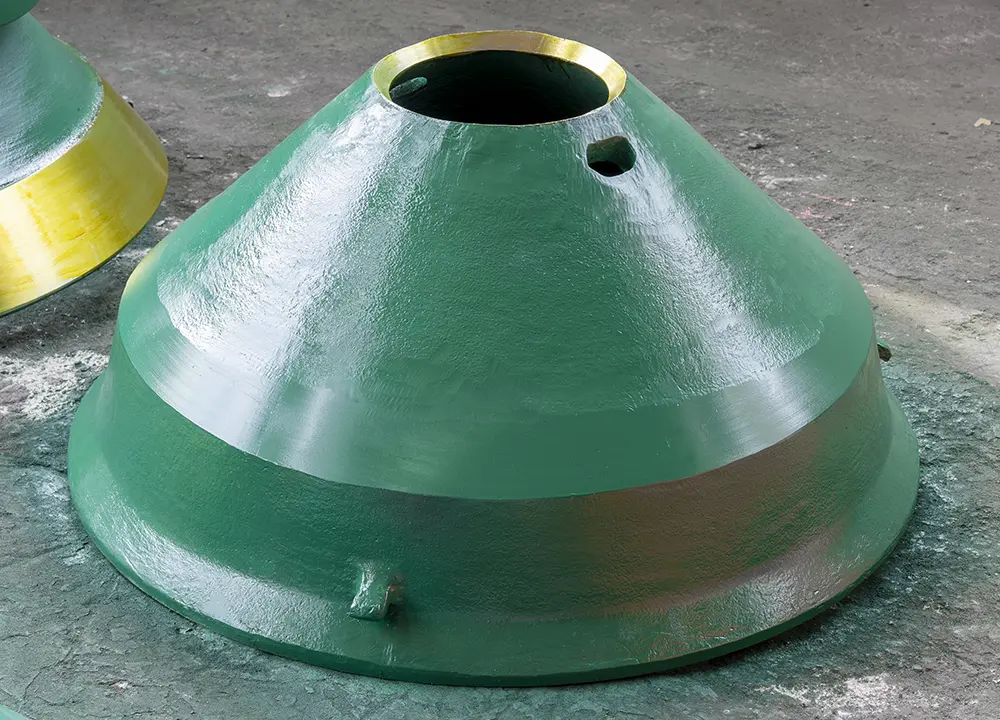

Mantle

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head. And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper accessories of the cone crusher.

HONGFEI cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

Our technical sales team, product engineers and pattern makers work closely together alongside our customers to develop and modify heavy duty jaw, cone and gyratory liner designs to further increase wear life.

video

Why Choose HONGFEI Mantle & Bowl Liner

① We offer OEM interchangeable cone crusher parts & liners;

② We offer a variety optional materials of cone crusher mantles and bowl liners;

③ We produce more wear-resistant products;

④ We extend the service life of the mantle and bowl liner;

⑤ We provide more competitive prices;

⑥ We provide more professional services and suggestions.

High Manganese Steel Cone Crusher Mantle & Bowl Liner

For the material of concave, HONGFEI use the Hadifield-steel , like Mn13Cr2,Mn18Cr2,Mn22Cr2, to ensure the wear resistance. Our cone parts are widely used on mining, constrution, chemical, cement and metallurgical indusery. After the modification treatment, combining with the special processing techniques, concave have a service life 10%-15% longer than those made of traditional materials.

Chemical Composition & Machanical Property Of High Manganese Materials

| Material | Chemical Composition (%) | Machanical Property | ||||

|---|---|---|---|---|---|---|

| Mn | Cr | C | Si | Ak/cm | HB | |

| Mn13Cr2 | 12-15 | 1.7-2.2 | 1.15-1.25 | 0.3-0.8 | >140 | ≤220 |

| Mn18Cr2 | 17-19 | 1.8-2.2 | 1.15-1.3 | 0.3-0.8 | >140 | ≤230 |

| Mn22Cr2 | 21-23 | 1.8-2.2 | 1.1-1.4 | 0.3-0.8 | >140 | ≤240 |