HONGFEI Products

High quality wear part

Jaw Crusher Wear Parts

Cone Crusher Wear Parts

Impact Crusher Wear Parts

More Parts

Capabilities

We have all your needs

Our engineers are always ready to listen to your ideas and concerns, and provide the solutions you need.

Although Zhejiang Hongfei Machinery Manufacturing Steel holds numerous patents, most of the innovative design takes place every day as engineers and field representatives work closely with end users to solve specific application problems. Incremental changes in design and optimum alloy selection often lead to significant improvements in the operation of equipment. Carefully studying the situation and identifying the problem or problems is key to developing improved wear parts that meet or exceed or customers’ needs.

Customized

Based on more than 20 years of experience, Zhejiang Hongfei Machinery Manufacturing Steel has developed our own proprietary series of alloys which exceed the classic ASTM minimum standards.

We offer one of the largest selections of wear- and heat-resistant alloys available from any single supplier. That provides many advantages to the end user. For example, we can supply all the various parts needed for a cement plant maintenance shutdown, from quarry to grinding mills to kiln to cooler. By varying the composition and heat treatment of our alloys, we are able to fine tune them, balancing toughness, hardness and/or heat and corrosion resistance for the specific application.

Metallurg Yalloys

Sand modelling casting-The organization structure is more exquisite and the product is more durable.

- Wood Model Making

- Modeling

- Casting

- Clean

- Shot Blasting

- Polished

- Inspection

- Machining

- Spraying

- Packing

- Delivery

Casting Process

Before production of any new or modified item, our sample procedures ensure that the casting will meet Zhejiang Hongfei Machinery Manufacturing Steel’s quality standards. Sample castings receive some or all of these quality tests, as appropriate:

- Compositional analysis

- Inspection for flaws or discontinuities

- Dimensional checking

- Hardness testing

- Radiographic analysis

- Ultrasonic testing

- Magnetic particle inspection

- Die penetrant inspection

- 3D scanner

Quality Assurance

HONGFEI

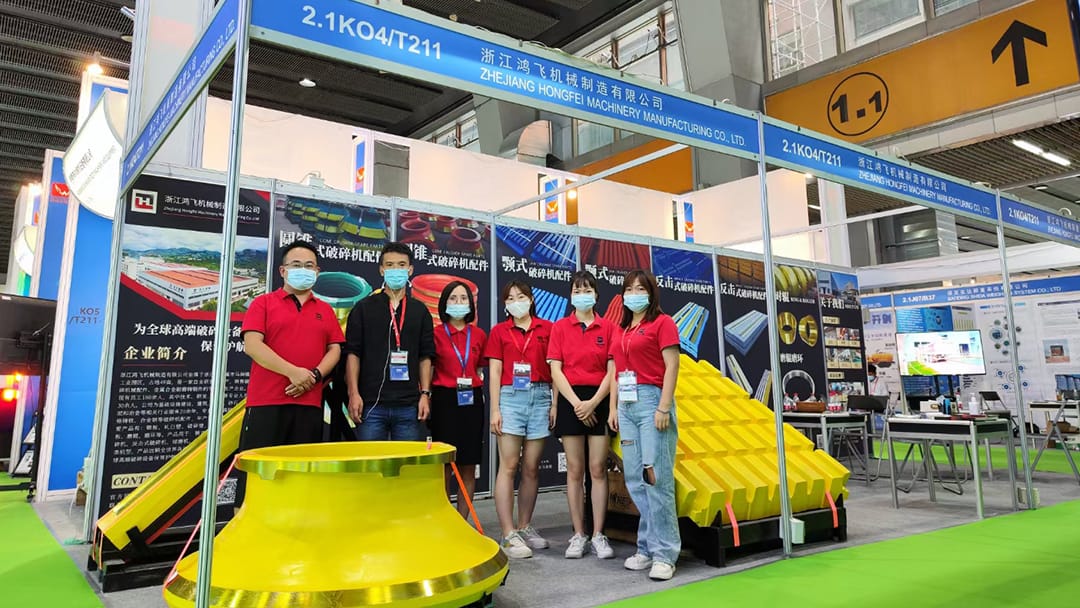

About Us

Professional Experience

Company Employees

Annual Output

Production Base

HONGFEI Introduction

We specialize in the production of high manganese steel, high chromium cast iron parts, annual output break through 15,000 tons.

HF has a comprehensive production base of more than 50,000 square meters ,with over 230 employees, and more than 30 technical, R&D and QC teams.